The Role of Robotics in Warehouse Optimization

Warehouses are the backbone of the global supply chain, serving as hubs where goods are stored, sorted, and dispatched to their destinations. In recent years, the integration of robotics into warehouse operations has revolutionized the way these facilities are managed, leading to increased efficiency, accuracy, and productivity. As technology continues to advance, the role of robotics in warehouse optimization is becoming increasingly significant.

Enhancing Efficiency with Automated Systems

One of the primary benefits of incorporating robotics into warehouse operations is the ability to enhance efficiency. Automated systems can perform repetitive tasks at a much faster pace and with greater precision than human workers. This not only reduces the time it takes to complete these tasks but also minimizes the risk of errors, leading to smoother and more streamlined operations.

For instance, robotic arms can be used to pick and pack items in a warehouse much faster than human workers, increasing the speed at which orders are fulfilled. Automated guided vehicles (AGVs) can transport goods around the warehouse, saving time and reducing the need for manual labor. By automating these processes, warehouses can operate more efficiently and handle a higher volume of orders with ease.

Improving Accuracy and Order Fulfillment

In addition to enhancing efficiency, robotics also play a crucial role in improving accuracy and order fulfillment rates in warehouses. With advanced technologies such as barcode scanners and computer vision, robots can quickly and accurately locate and retrieve items from storage locations. This not only reduces the likelihood of errors but also ensures that orders are fulfilled correctly and on time.

Furthermore, robots can work around the clock without getting tired or making mistakes due to fatigue, leading to more consistent and reliable performance. This is especially important in industries where precision and speed are essential, such as e-commerce and manufacturing. By leveraging robotics in warehouse operations, businesses can significantly improve their order fulfillment rates and customer satisfaction levels.

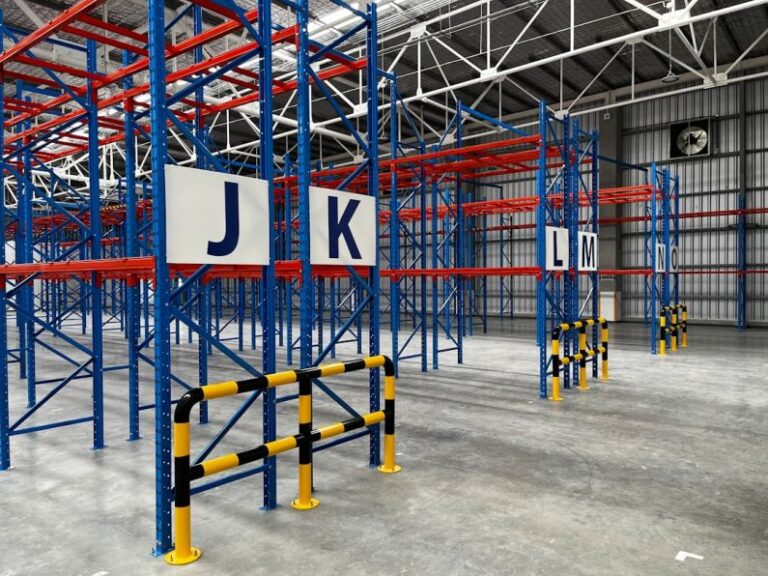

Optimizing Space Utilization and Inventory Management

Another key aspect of warehouse optimization that robotics can address is space utilization and inventory management. By using automated systems to stack and retrieve goods, warehouses can maximize their storage capacity and make better use of available space. This is particularly beneficial for facilities with limited square footage or those looking to expand their storage capabilities without incurring significant costs.

Moreover, robotics can help warehouses keep track of their inventory in real-time, reducing the likelihood of stockouts or overstock situations. By using sensors and data analytics, robots can monitor inventory levels, identify trends, and make recommendations for restocking or replenishment. This proactive approach to inventory management can prevent costly disruptions in the supply chain and ensure that goods are always available when needed.

Enhancing Workplace Safety and Employee Satisfaction

In addition to improving operational efficiency and accuracy, robotics also play a crucial role in enhancing workplace safety and employee satisfaction in warehouses. By automating tasks that are physically demanding or pose safety risks to workers, robots can help reduce the incidence of work-related injuries and accidents. This not only creates a safer work environment but also boosts employee morale and satisfaction.

Furthermore, by delegating repetitive and labor-intensive tasks to robots, warehouse workers can focus on more strategic and high-value activities that require human creativity and problem-solving skills. This shift in responsibilities can lead to a more engaged and motivated workforce, ultimately driving productivity and innovation within the organization. Overall, the integration of robotics in warehouse operations can have a positive impact on both workplace safety and employee satisfaction levels.

In Conclusion

As warehouses continue to evolve in response to changing market demands and technological advancements, the role of robotics in optimizing these facilities is becoming increasingly vital. From enhancing efficiency and accuracy to improving space utilization and inventory management, robots are revolutionizing the way warehouses operate. By leveraging the power of automation and artificial intelligence, businesses can streamline their operations, reduce costs, and deliver exceptional service to customers. Moving forward, the integration of robotics in warehouse optimization will be essential for staying competitive in the fast-paced world of supply chain management.