The Future of Warehouse Automation

In recent years, warehouse automation has been rapidly transforming the way goods are stored, picked, and shipped in distribution centers around the world. As technology continues to advance at a rapid pace, the future of warehouse automation looks promising, with innovations poised to further improve efficiency, accuracy, and speed in the supply chain industry.

**Evolution of Warehouse Automation**

The evolution of warehouse automation can be traced back to the introduction of conveyor belts and forklifts, which revolutionized the way goods were moved within a warehouse. However, with the advent of robotics, artificial intelligence, and the Internet of Things (IoT), warehouses are now becoming increasingly automated and interconnected.

**Robotics and Autonomous Vehicles**

One of the most significant advancements in warehouse automation is the use of robotics and autonomous vehicles. These technologies have enabled warehouses to streamline their operations by automating tasks such as picking, packing, and sorting. Robots equipped with sensors and cameras can navigate through warehouses, identify items, and transport them to the desired location with precision and efficiency. Autonomous vehicles, such as drones and self-driving forklifts, are also being increasingly used to transport goods within warehouses, reducing the need for human intervention and speeding up the fulfillment process.

**Artificial Intelligence and Machine Learning**

Artificial intelligence (AI) and machine learning have also played a crucial role in the advancement of warehouse automation. AI-powered systems can analyze vast amounts of data in real-time to optimize inventory management, predict demand, and improve supply chain efficiency. Machine learning algorithms can also be used to optimize warehouse layout, picking routes, and storage locations, leading to reduced operational costs and increased productivity.

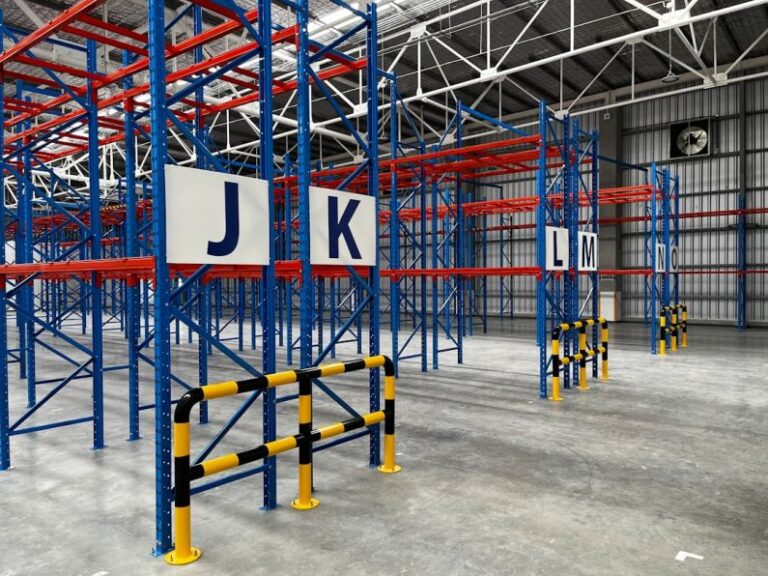

**Internet of Things (IoT) and Connectivity**

The Internet of Things (IoT) has enabled warehouses to become more interconnected and intelligent. By connecting devices, equipment, and systems through the internet, warehouses can collect and share data in real-time, allowing for better decision-making and operational efficiency. IoT sensors can monitor inventory levels, track the movement of goods, and even detect potential maintenance issues before they escalate, leading to improved reliability and reduced downtime.

**Emerging Technologies**

Looking ahead, emerging technologies such as 5G connectivity, augmented reality, and blockchain are poised to further revolutionize warehouse automation. 5G connectivity will enable faster data transfer speeds and lower latency, allowing for more responsive and efficient warehouse operations. Augmented reality can be used to guide workers through complex picking processes, reducing errors and increasing productivity. Blockchain technology can enhance supply chain transparency and traceability, ensuring the authenticity and provenance of goods throughout the warehouse process.

**Challenges and Opportunities**

While the future of warehouse automation holds great promise, there are also challenges that need to be addressed. One of the main challenges is the integration of these advanced technologies into existing warehouse systems and processes. Companies will need to invest in training their workforce to adapt to these new technologies and ensure a smooth transition to automated processes. Additionally, cybersecurity threats and data privacy concerns will need to be addressed to safeguard sensitive information and prevent potential disruptions in warehouse operations.

**Conclusion: A Bright Future Ahead**

In conclusion, the future of warehouse automation is bright, with innovative technologies poised to transform the supply chain industry. Robotics, artificial intelligence, IoT, and emerging technologies will continue to drive efficiency, accuracy, and speed in warehouse operations, leading to improved customer satisfaction and reduced costs. By embracing these advancements and addressing the challenges that come with them, companies can stay ahead of the curve and unlock the full potential of warehouse automation in the years to come.